Specialist Divers Enable Successful HDD Cable Pull Operation for Major Energy Project

Client / Site: NKT Cables – HVDC Cable Route, East Coast Landfall, UK

The Challenge

NKT needed specialist diving support for a critical phase of their HVDC (High Voltage Direct Current) export cable project. The operation involved HDD diving support for a Horizontal Directional Drilling landfall connection, where underground drilling creates a pathway from land to sea for major cable installations.

This HDD diving support operation presented multiple technical challenges:

- Locating the submerged HDD punch-out point – finding the exact exit point of the underground drill

- Variable seabed conditions – dealing with changing underwater terrain and sediment types

- Low visibility operations – working in murky coastal waters with limited sight

- Tidal surge management – coordinating work around powerful tidal movements

- Precision pull-head engagement – connecting cables with accuracy underwater

- Live vessel coordination – working alongside active cable lay vessels and barges

- Tight marine operations window – limited weather windows for offshore work

- Zero-failure timeline – any delays would impact multiple project milestones

The client required seamless HDD diving support with absolute precision, as the offshore lay vessel commitments meant there was no room for error or delays.

Our Response

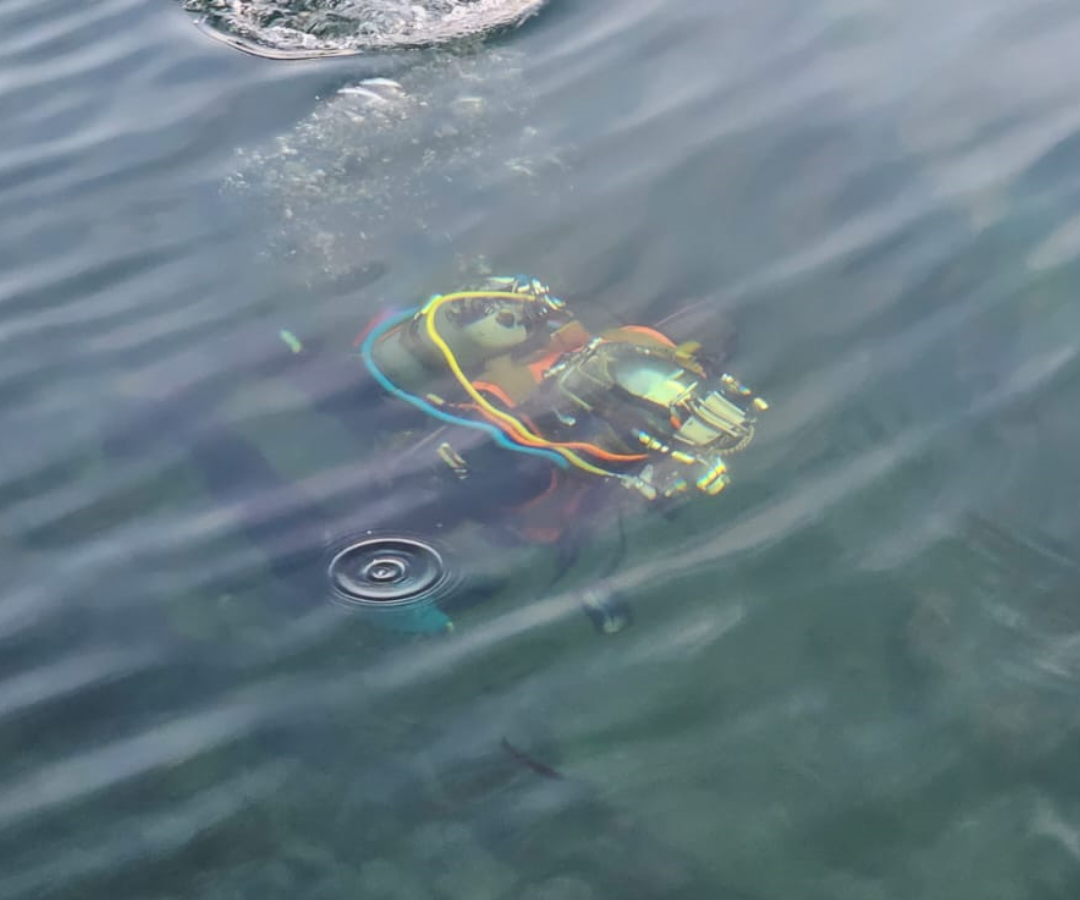

Dagger Diving Services deployed a specialist HDD diving support team with advanced surface-supplied diving systems and precise tidal planning capabilities.

Pre-Operation Preparation Our HDD diving support specialists conducted comprehensive subsea verification of the HDD exit trench using tactile and acoustic methods. Working in challenging visibility conditions, divers systematically removed silt, gravel, and clay plugs using suction and water-dredging techniques to ensure a clear drill path.

Precision Positioning Systems Pull-head alignment was achieved using tensioned rigging and subsea positioning markers, installed by our dive team in advance. This preparation ensured highly-accurate positioning for the critical cable pull-in phase.

Advanced Diving Operations

- Surface-supplied dive spread – providing reliable air supply and communication

- Dynamic coordination – real-time collaboration with HDD contractors and cable lay teams

- Tidal planning – pre-programmed operations around optimal tidal windows

- Live topside communications – constant coordination during high-tension operations

Critical Pull-In Phase

During the actual cable pull-in, our HDD diving support team engaged and secured the pull-head for cable transition through the HDD duct, standing by throughout the full tension pull-in process with continuous topside communication.

Quality Assurance

Post-installation, divers conducted comprehensive as-built checks, documenting depth of burial, duct integrity, and slack management at the trench interface to ensure long-term cable protection.

The Outcome

Flawless Execution – First-Time Success

Our HDD diving support operation delivered exactly what NKT needed: precision execution with zero delays and perfect technical results.

Operational Excellence:

- HDD landfall completed without delay or deviation

- Cable pull-in executed successfully on the first attempt

- Zero downtime throughout the entire operation

- Seamless subsea interface support maintained project schedule

Technical Achievement:

- 6 dive days completed in challenging conditions

- Full HDD punch-out verification and clearance achieved

- Complete trench interface validation ensuring cable protection

Documentation & Compliance:

- QA documentation submitted within 24 hours

- As-built handover delivered on schedule

- Trench verification reports provided for Marine Warranty Surveyor review

- Full environmental protection maintained throughout

Project Impact: NKT remained on schedule with their wider export cable programme, enabling the renewable energy project to proceed without costly delays.

Safety & Standards: All operations were executed under IMCA D014/D018 and ISO 9001, 45001, 14001 standards, with full environmental protection, subsea quality assurance, and trench interface validation. Coordination with marine assets met all navigational and project safety protocols.

Planning a cable installation project requiring diving support? Dagger Diving Services specializes in precision subsea operations for HDD landfall connections. Contact us today to discuss your HDD diving support requirements.